Contact Advisory

1900 63 80 87

Contact Advisory

1900 63 80 87

14/11/2021

0 Comment

Share

Expand the lifespan of your batteries: lead sulfate is removed by the electrical high-frequency pulsation process of the battery reconditioner. Rejuvenate your battery!

Battery reconditioning is very popular. 80% of the batteries breaking down and losing capacity are sulfated, but can be restored with the right equipment. Our Energic Plus battery regenerator successfully removes sulphation due to an electrical high-frequency pulsation process. This process restores the battery capacity, giving you the ability to reuse old and sulfated batteries. You can also use the battery reconditioner for annual maintenance to strongly prolong the lifespan of your batteries.

Starter batteries – Stationary batteries – (Semi-)traction batteries – Ni-Cad batteries

Our Energic Plus battery reconditioners are specialized on forklift batteries. Besides reconditioning forklift batteries, the device has other fields of application: Golf Cart, Wheelchair, UPS, Automotive vehicle, Heavy Equipment, Military, Agricultural Machine, Motorbike, Boat, Train, Wind & Solar Power System and others.

When a battery’s energy charge is drained and needs to be charged during normal working cycles, sulfate crystals gradually build up on the electrodes, preventing the battery from effectively delivering current. The crystals in effect suffocate the battery.

This lead sulfate increases internal resistance and decreases the specific gravity of the electrolyte. The process of battery sulfation build-up is unavoidable. Worse yet, after 3-4 years the process accelerates substantially.

Battery sulphation is a result of many reasons. Here are the main causes:

The battery was inactive for too long.

A battery desulfator or reconditioner is an electronic device that cleans the internal battery plates to remove lead sulfate. This lead sulfate will form on the batteries internal plates and greatly reduces the capacity of a charge on a battery. By restoring the lead sulfate back into the acid solution you can greatly extend the life of the battery.

By using our Battery Regenerator you will be able to dissolve the hardened sulfate and restore it to active material. It uses high-frequency wrinkle currents that are very effective in removing the hardened sulfate.

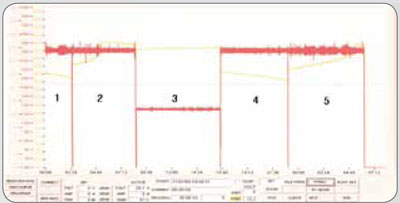

The desulfation process is fully automatic (max 42 hours), temperature-controlled and consists of 5 steps. This results in increased electrolyte gravity, reduced inner resistance, and increased battery capacity.

Our Battery Reconditioner comes with monitoring software. This software allows you to:

The REPLUS battery desulfator has an extremely user-friendly control panel. Via “Setting” you can change the date and modify some screen settings and in “Operation” you can configurate the final settings for the battery reconditioning process. This curve shows a complete restoration:

When you compare discharge 1 to 4, you see that the time needed to discharge the battery has more than doubled during the second discharge. This is a direct result of the HF pulse process during steps 2 and 3.

Same story in step 5: when comparing this step to step 2, you see that the set battery voltage is reached much later than in step 2. This means that your battery lasts longer, is accepting current again and is thus recovered.

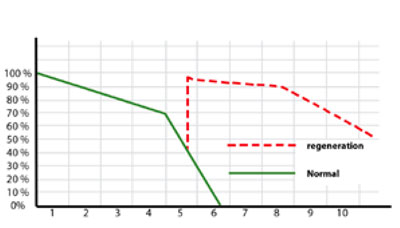

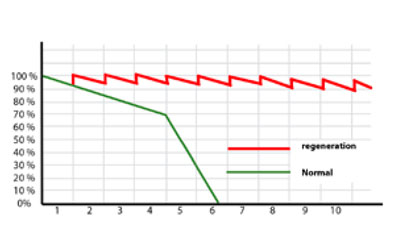

There are two ways to use the battery reconditioner: reconditioning regeneration and maintenance regeneration.

Reconditioning regeneration allows you to restore old (5, 6, 7 … years), medium to well-maintained batteries that have ‘silted up’ to a 90-100% productivity, as a result of natural sulphation.

Maintenance regeneration allows you to keep your battery in optimal, sulfate-free condition, by means of a yearly short regeneration.

Energic Plus has become the specialist in equipment for battery regeneration in the last 5 years. With more than 500 happy and returning customers in all continents of the world, we can say that we are the leading supplier of equipment in today’s market. With the battery regeneration technology, you can use your batteries longer and that saves a lot of CO2. That way, the regenerator contributes to a better environment.

Our battery desulfation technology is specifically designed to analyze and regenerate and restore all types of lead-acid batteries, we have very nice references in different industry sectors. Material handling is our biggest market with big names like Linde and Toyota who have both bought several machines to be used by their official dealers.

WE ARE COMMITTED TO PROVIDE THE RIGHT DEVICES AND SERVICES YOU NEED

Contact us

1900 63 80 87

Gửi Yêu Cầu Đến Chúng Tôi Để Được Hỗ Trợ Tư Vấn Sản Phẩm & Dịch Vụ Bạn Cần